This site is also available on:

Deutsch

The German Aerospace Center (DLR) sees new load control systems as an opportunity to increase the efficiency of flying. By reducing pollution and fuel consumption, this technology could improve both passenger comfort and the environmental footprint of air travel.

Innovative control surfaces for load control

The DLR researchers emphasized that intelligent load control systems can make aircraft more efficient and comfortable. These systems quickly adjust control surfaces during gusts of wind and maneuvers. Experts emphasize that this technology can reduce wing material stress and increase passenger comfort. According to estimates, fuel consumption will fall by up to 7.2%, while at the same time a significant reduction in CO₂ emissions is expected.

Technology and sensors

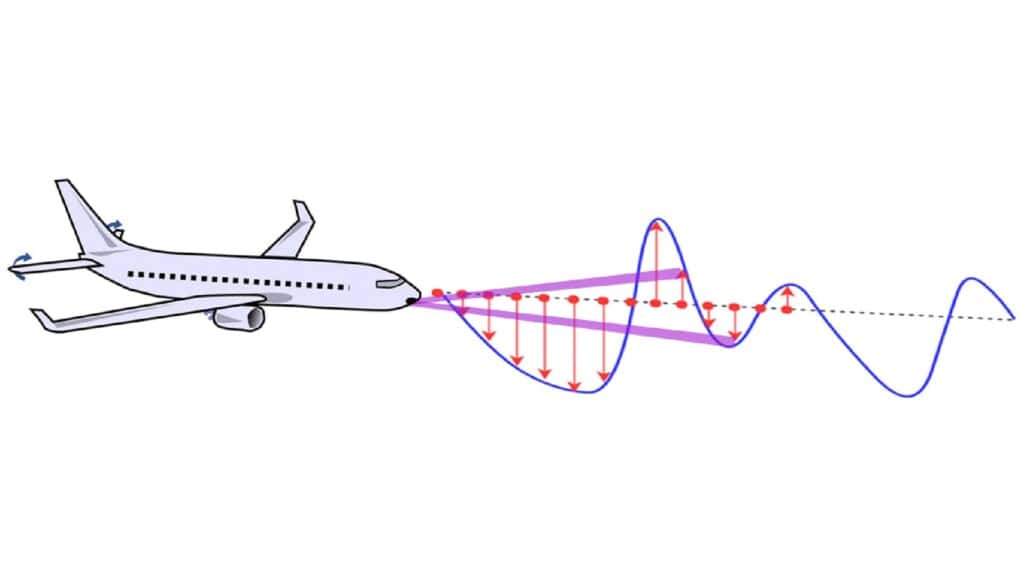

Dr. Lars Reimer from the DLR Institute of Aerodynamics and Fluid Dynamics explained the use of sensors such as laser systems and LiDAR. These sensors identify wind fields at an early stage and react precisely to external influences. This technological advance allows aircraft to better withstand structural loads and respond proactively to external disturbances, improving the aerodynamics and efficiency of modern aircraft.

Simulations and experimental confirmations

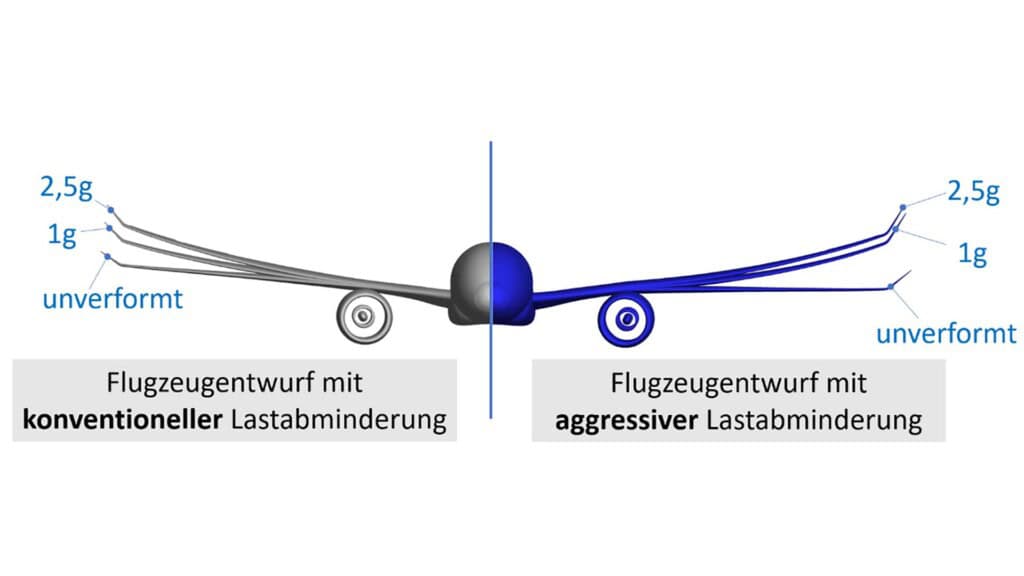

Within the oLAF project, comprehensive analyzes were carried out that demonstrate the positive effect of load reduction on the design of long-haul aircraft. Simulations show that aircraft with aggressive load reduction are significantly more aerodynamic and efficient than traditional models. Tests in the low-speed wind tunnel in Braunschweig confirmed that the vibrations on the wing can be reduced by 80%, which significantly reduces the load on the material.

Future implications for aviation

DLR experts predict that the new technology will enable lighter wing concepts and up to 7.2% less fuel consumption. Despite potentially increased maintenance costs, profitability could be increased by up to 6.7%. Dr. Reimer commented that load control is now considered a key component for future aircraft designs, with optimal aerodynamics and increased efficiency.

The German Aerospace Center (DLR) is a leading research institute in aerospace. It is committed to the development of sustainable technologies in aviation and strives to implement scientific knowledge in practical applications to make aviation more efficient and environmentally friendly.

DLR expands: technology in aviation

The German Aerospace Center (DLR) plans to further develop the existing technology and test selected prototypes in research aircraft. In parallel, the digital design process is being optimized, integrating all relevant disciplines to provide aircraft manufacturers with innovative load reduction technologies.

Flying Efficiently: Research and Development

The German Aerospace Center (DLR) is working on the further development of cutting-edge technologies for aviation. The organization plans to test prototypes of these technologies in its research aircraft. The aim is to facilitate the integration of these innovations into the early design phase of new aircraft by providing high-precision tools. This step could make the design processes significantly more efficient and set new standards in this regard.

Digital design processes

In parallel to testing the prototypes, the digital design process will continue as part of the oLAF project. The process integrates disciplines such as aerodynamics, structure and load control to create a comprehensive, digital model. This model allows aircraft manufacturers to access precise technological solutions that contribute to load reduction at an early stage. The further development of this digital process is crucial for the future of aviation technology.

Procedure and tools

DLR aims to develop a detailed approach that can be used by aircraft manufacturers in the design phase. The use of digital tools is intended to reduce the effort in the preliminary design phase and increase precision. This is achieved by providing innovative and precise tools that enable the integration of load mitigation technologies. These tools are intended to help manufacturers develop more efficient and safer designs right from the start.

Future outlook

DLR’s progress could have a significant impact on the future of aviation. By integrating modern technologies and optimizing design processes, aircraft are expected to be made more efficient and sustainable. Such innovations could reduce CO2 emissions and increase safety in aviation, which is why the DLR initiatives are highly relevant for the industry. In the long term, this could strengthen the competitiveness of European aircraft manufacturers.

The German Aerospace Center (DLR) is one of the leading institutions for research and development in aerospace technology. With a clear focus on innovation and sustainability, DLR carries out projects that aim to promote technological advances and solutions in the field of aviation.